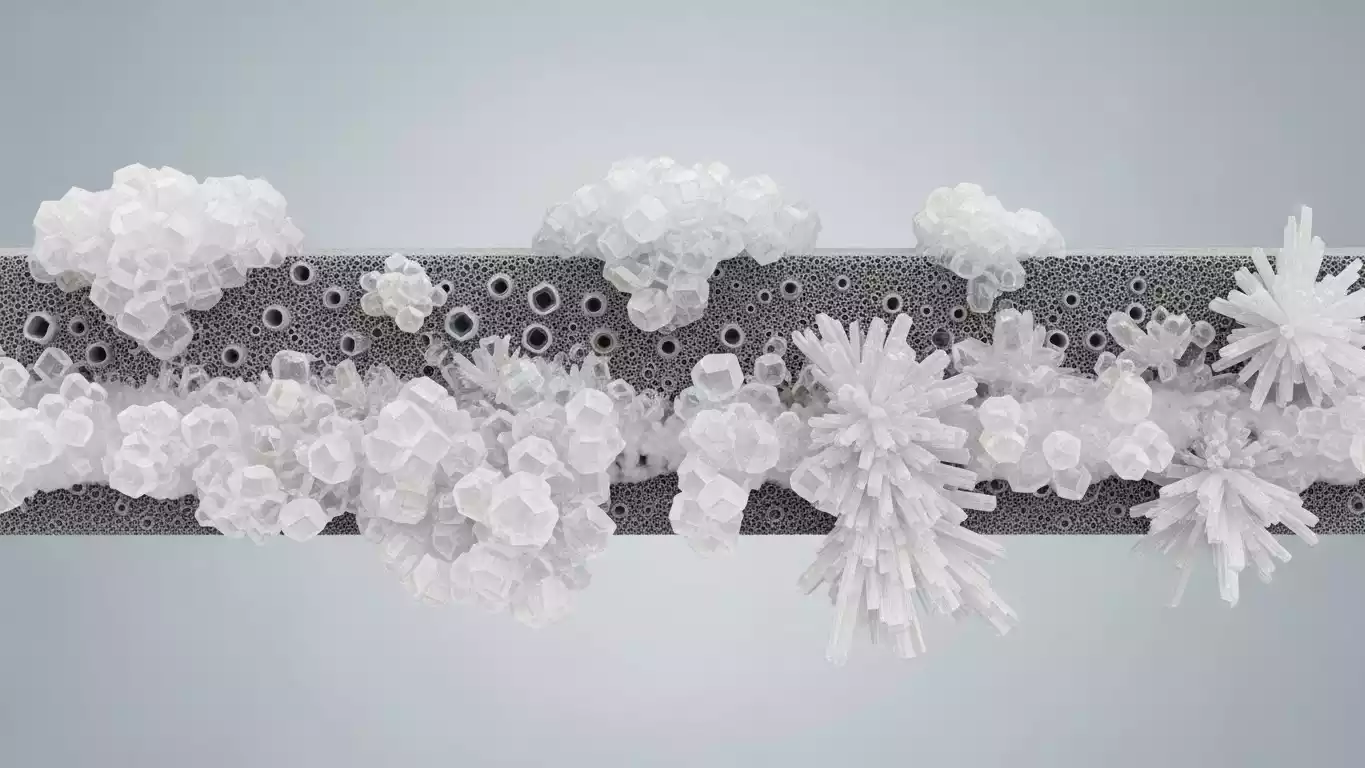

Scaling is one of those silent problems in water treatment. It does not knock on the door or send a warning email. It simply builds up, damages membranes, increases pressure, and quietly raises operating costs. That is exactly why an Antiscalant Dosing Calculator matters more than most people realize.

If you work with reverse osmosis (RO) systems, industrial water treatment, or desalination plants, this guide is for you. We will explain what an antiscalant dosing calculator is, how it works, why accuracy matters, and how to use it properly-without confusing jargon or guesswork.

Let’s break it down in a clear, logical, and practical way.

What Is an Antiscalant Dosing Calculator?

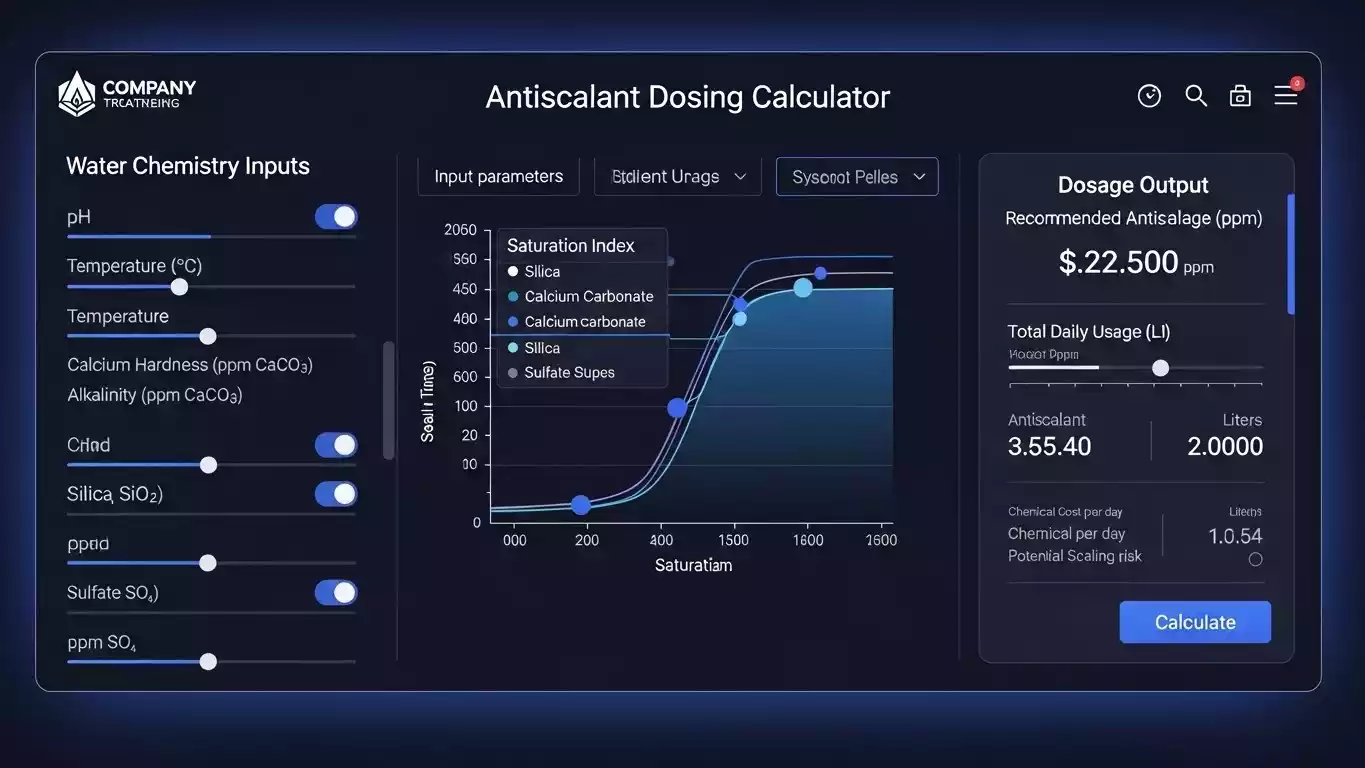

An antiscalant dosing calculator is a tool that helps determine the correct amount of antiscalant chemical required to prevent scale formation in water systems.

Scale forms when minerals like calcium carbonate, calcium sulfate, or barium sulfate exceed their solubility limits. These minerals then stick to membranes and pipes like uninvited guests who refuse to leave.

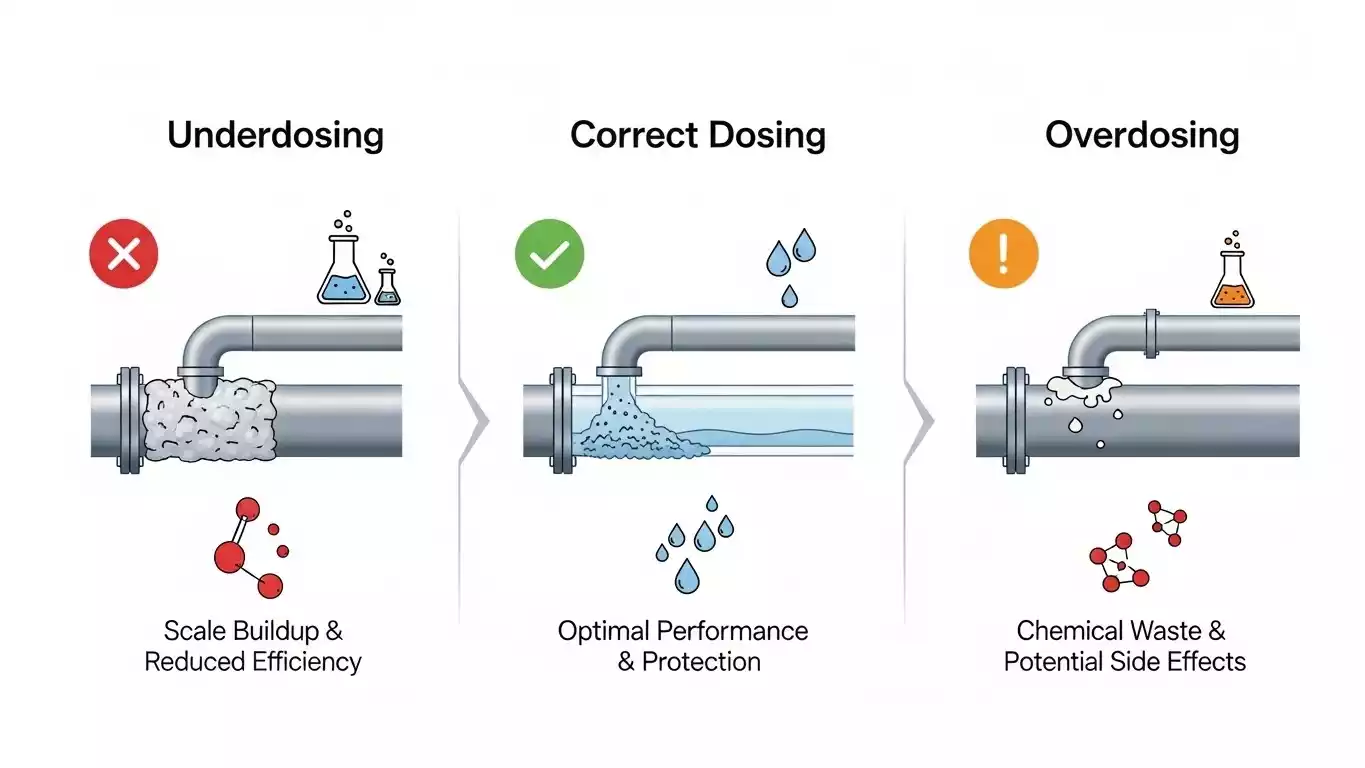

The calculator uses water chemistry data and system parameters to recommend a precise antiscalant dose. This approach prevents overdosing, underdosing, and unnecessary chemical waste.

In short, it answers one important question:

How much antiscalant should I dose to protect my system-without wasting money or damaging equipment?

Why Antiscalant Dosing Accuracy Matters

Guessing the dose is tempting. It also causes expensive problems.

1. Underdosing Causes Scaling

Too little antiscalant allows scale to form. Scale reduces membrane permeability, increases energy consumption, and shortens membrane life.

2. Overdosing Wastes Money

More antiscalant does not equal better protection. Overdosing increases operating costs and may cause fouling in some systems.

3. Membrane Warranty Compliance

Most membrane manufacturers, including DuPont (FilmTec) and Toray, require correct antiscalant dosing for warranty validity. Incorrect dosing may void coverage.

Accuracy protects your equipment, budget, and peace of mind.

How an Antiscalant Dosing Calculator Works

An antiscalant dosing calculator relies on real chemical principles, not assumptions.

It typically considers the following inputs:

Feed Water Chemistry

- Calcium

- Magnesium

- Bicarbonate

- Sulfate

- Chloride

- Silica

- pH

- Total Dissolved Solids (TDS)

These values usually come from a laboratory water analysis report.

System Operating Conditions

- Feed flow rate

- Recovery percentage

- Temperature

- Operating pressure

Each factor affects scaling potential.

Antiscalant Product Type

Different antiscalants have different performance limits. Manufacturers provide dosing ranges and maximum saturation indices.

The calculator then estimates the minimum effective dose, usually expressed in mg/L or ppm.

Key Benefits of Using an Antiscalant Dosing Calculator

Using a calculator is not about convenience. It is about control.

Consistent Performance

Accurate dosing stabilizes system performance and reduces unplanned shutdowns.

Cost Optimization

You use only the chemical you actually need. Your chemical budget will thank you.

Extended Membrane Life

Scaling is one of the main reasons membranes fail early. Prevention saves replacement costs.

Regulatory and Manufacturer Compliance

Correct dosing aligns with industry guidelines and membrane supplier recommendations.

Common Types of Antiscalants Used in Calculations

Not all antiscalants behave the same way. A good calculator accounts for the product type.

Phosphonate-Based Antiscalants

These are widely used and effective against calcium carbonate and calcium sulfate scaling.

Polymer-Based Antiscalants

These perform well at higher recoveries and control a broader range of scales.

Specialty Antiscalants

Some products target silica or barium sulfate specifically. Calculators must respect their maximum limits.

Always rely on manufacturer technical datasheets when selecting a product.

How to Use an Antiscalant Dosing Calculator Step by Step

Let’s keep this simple and practical.

Step 1: Obtain a Recent Water Analysis

Use laboratory-tested feed water data. Old or estimated data leads to wrong results.

Step 2: Enter System Parameters

Add flow rate, temperature, recovery, and operating pressure accurately.

Step 3: Select the Antiscalant Product

Choose the exact product name. Different brands use different dosing logic.

Step 4: Review the Recommended Dose

The calculator will suggest a dose in ppm or mg/L.

Step 5: Cross-Check with Manufacturer Guidelines

Always confirm that the calculated dose falls within the product’s recommended range.

This final check protects both your system and your credibility.

Common Mistakes to Avoid When Calculating Antiscalant Dosage

Even experienced operators make these mistakes.

Using Incomplete Water Analysis

Skipping silica or sulfate values often leads to underdosing.

Ignoring Temperature Effects

Higher temperatures increase scaling potential. The calculator needs this input.

Blindly Trusting One Tool

Always validate results with manufacturer software or expert review when possible.

Forgetting Recovery Changes

Any recovery adjustment changes scaling risk. Recalculate when recovery changes.

Antiscalant Dosing Calculator vs Manual Calculations

Manual calculations still exist, but they carry risks.

| Factor | Calculator | Manual Method |

|---|---|---|

| Accuracy | High | Medium |

| Time Required | Low | High |

| Error Risk | Low | High |

| Scalability | Excellent | Limited |

Modern water treatment relies on calculators because consistency matters more than tradition.

Trusted Sources Behind Antiscalant Calculations

Reputable calculators follow principles published and validated by trusted organizations, such as:

- American Water Works Association (AWWA)

- International Water Association (IWA)

- Membrane manufacturers like DuPont, Toray, and Hydranautics

- Peer-reviewed water chemistry research

These sources define saturation indices, solubility limits, and safe dosing ranges. Reliable calculators do not invent data. They apply proven chemistry.

Who Should Use an Antiscalant Dosing Calculator?

This tool is not limited to engineers.

- RO plant operators

- Water treatment consultants

- Industrial facility managers

- Desalination plant technicians

- OEM system designers

If scaling affects your system, this calculator belongs in your toolbox.

Frequently Asked Questions (FAQs)

What is the ideal antiscalant dosage?

There is no universal dose. The ideal dosage depends on feed water chemistry, system recovery, and antiscalant type. A dosing calculator provides a system-specific value.

Can I overdose antiscalant safely?

Overdosing does not improve protection and may increase fouling risks. Always stay within the manufacturer’s recommended range.

How often should I recalculate antiscalant dosage?

Recalculate whenever feed water quality, temperature, or system recovery changes. Seasonal variations often require adjustment.

Are online antiscalant dosing calculators reliable?

They are reliable when based on manufacturer data and validated chemical models. Always confirm results with product datasheets.

Does antiscalant replace water softening?

No. Antiscalants prevent scale formation but do not remove hardness ions. Softening and antiscalant dosing serve different purposes.

Final Thoughts: Precision Beats Guesswork

Water treatment rewards precision. Scaling does not forgive shortcuts, and membranes do not tolerate assumptions.

An antiscalant dosing calculator gives you clarity, control, and confidence. It helps you protect equipment, control costs, and operate responsibly-without unnecessary complexity.

Use real data. Trust proven chemistry. And let the calculator do what it does best: keep scale out of your system and stress out of your workday.

Because in water treatment, prevention always costs less than repair.